Let’s dive into the world of electronic circuits where capacitors take center stage as a crucial component. Traditionally, capacitors have served key functions such as bypass coupling, power filtering, DC blocking, and aiding oscillation and signal delay. However, as electronic circuits evolve, particularly in the realm of power electronics, unique demands emerge for capacitors in various contexts.

A basic capacitor consists of two plates with an insulating dielectric material in between, which can include air. When the capacitor is charged, a voltage or potential difference is established across the plates. However, the insulating material prevents current flow through the capacitor, provided that the voltage does not exceed its breakdown voltage. Breakdown voltage refers to the threshold at which the insulating material becomes conductive due to the increase in voltage. It is important to note that all substances have some degree of insulation, and once the voltage surpasses a certain level, the substance will begin to conduct electricity.

Capacitors are no exception. After the capacitor is broken down, it is no longer an insulator. However, in the middle school stage, such voltage is not seen in the circuit, so they all work below the breakdown voltage and can be regarded as an insulator. However, in an AC circuit, the direction of the current changes as a function of time. The process of charging and discharging the capacitor has time. At this time, a changing electric field is formed between the plates, and this electric field is also a function of changing with time.

Filter capacitor

After rectification, an alternating current (AC) power signal, whether at power frequency or high frequency, requires the use of a capacitor to filter and smooth the output voltage. This typically necessitates a capacitor with a large capacity, for which aluminum electrolytic capacitors are commonly employed. However, a key concern with these capacitors is their lifespan in relation to temperature, which follows the general 50°C rule. In applications requiring high temperature tolerance and reliability, it is advisable to select long-life electrolytic capacitors, such as those rated for more than 5000 hours or even 105°C for 5000 hours. It should be noted that smaller electrolytic capacitors tend to have shorter lifespans.

One specific application for these capacitors is in the input filter of DC/DC switching regulated power supplies. As switching converters draw power in pulse form from the power supply, the filter capacitor experiences a high-frequency current surge. If the equivalent series resistance (ESR) of the electrolytic capacitor is significant, it will result in substantial losses and heat generation. The use of low-ESR electrolytic capacitors can effectively reduce heat generated by ripple currents, particularly at high frequencies.

Electrolytic capacitors used for output rectification of switching regulated power supplies require that their impedance frequency characteristics do not show an upward trend at 300kHz or even 500kHz. However, ordinary electrolytic capacitors begin to show an upward trend after 100kHz, and the effect of rectifying and filtering the output of switching power supplies is relatively poor. The author found in the experiment that the ripple and peak of the common CDII type 4700μF, 16V electrolytic capacitor used for switching power supply output filtering is not lower than that of the CD03HF type 4700μF, 16V high-frequency electrolytic capacitor, and the temperature rise of the common electrolytic capacitor is relatively high. When the load is abrupt, the transient response of ordinary electrolytic capacitors is far inferior to that of high-frequency electrolytic capacitors.

Also Read: Working principle of capacitor in DC-DC converter

To compensate for the limitations of aluminum electrolytic capacitors in the high frequency range, it is advisable to complement them with ceramic or non-inductive film capacitors that exhibit good high frequency characteristics. These additional capacitors offer several advantages, including:

- Good high frequency characteristics: Ceramic or non-inductive film capacitors perform well in high frequency applications, ensuring effective filtering and smoothing of the output voltage.

- Low equivalent series resistance (ESR): Capacitors such as MMK5 with a capacity of 1μF have a resonant frequency above 2MHz and an equivalent impedance below 0.02Ω, significantly lower than that of electrolytic capacitors. This low ESR helps minimize losses and heat generation.

- Higher resonant frequency with smaller capacitance: The resonant frequency of these capacitors increases as the capacitance decreases, potentially reaching 50MHz or even higher. This allows for better output frequency response and dynamic response of the power supply.

Filter capacitors play a crucial role in switching power supplies, and the correct selection of filter capacitors, particularly output filter capacitors, is a matter of great importance for engineers. By combining aluminum electrolytic capacitors with capacitors possessing good high frequency characteristics, engineers can optimize the performance and reliability of the power supply.

Common electrolytic capacitors used in 50 Hz power frequency circuits have a pulsating voltage frequency of only 100 Hz, and charge and discharge times are on the order of milliseconds. In order to obtain a smaller pulsation coefficient, the required capacitance is as high as hundreds of thousands of microfarads. Therefore, the goal of ordinary low-frequency aluminum electrolytic capacitors is to increase the capacitance. The capacitance, loss tangent and leakage current of the capacitor are the main parameters to identify its advantages and disadvantages. The output filter electrolytic capacitor in the switching power supply has a sawtooth wave voltage frequency as high as tens of thousands of hertz, or even tens of megahertz. At this time, the capacitance is not the main indicator, and the standard for measuring the quality of high-frequency aluminum electrolytic capacitors is the “impedance-frequency” characteristic. It is required to have a lower equivalent impedance within the operating frequency of the switching power supply, and at the same time have a good filtering effect on the high-frequency spike signals generated when the semiconductor device is working.

When it comes to filter capacitors used in the output of switching power supplies, they differ from those selected for industrial frequency circuits. The pulsating voltage frequency on the output filter capacitor is typically around 100 Hz. The primary parameters that determine the advantages and disadvantages of aluminum electrolytic capacitors used in this application are capacitance, equivalent series resistance (ESR), loss angle tangent value, and leakage current.

In a switching regulated power supply, the output filter electrolytic capacitor experiences a sawtooth wave voltage with frequencies ranging from tens of kilohertz to even tens of megahertz. Unlike low-frequency applications, the capacitance value is not the main determining factor for these capacitors. Instead, their impedance-frequency characteristics play a crucial role in measuring their quality.

These capacitors need to exhibit low impedance within the operating frequency band of the switching regulated power supply. However, when the frequency approaches 1000 Hz, their impedance tends to become inductive, which does not meet the requirements of switching power supplies. Therefore, simply relying on capacitance value alone may not be sufficient when selecting filter capacitors for switching power supply applications. Impedance characteristics at the intended operating frequencies should be carefully considered to ensure optimal performance.

Ordinary low-frequency electrolytic capacitors begin to show inductance at about 10,000 Hz, which cannot meet the requirements of switching power supplies. The high-frequency aluminum electrolytic capacitor dedicated to the switching power supply has four terminals. The two ends of the positive aluminum sheet are respectively drawn out as the positive electrode of the capacitor, and the two ends of the negative aluminum sheet are also respectively drawn out as the negative electrode. The current flows in from one positive terminal of the four-terminal capacitor, passes through the capacitor, and then flows from the other positive terminal to the load; the current returning from the load also flows in from one negative terminal of the capacitor, and then flows from the other negative terminal to the negative terminal of the power supply.

The high-frequency aluminum electrolytic capacitor used in switching power supplies is equipped with four terminals. The positive terminal of the capacitor is connected to both ends of the positive aluminum foil, while the negative terminal is connected to both ends of the negative aluminum foil. In the switching power supply circuit, the current flows into one of the positive terminals of the four-terminal capacitor, passes through the capacitor’s internals, and then exits from the other positive terminal towards the load. Similarly, the current returning from the load enters one of the negative terminals of the capacitor and exits from the other negative terminal towards the negative terminal of the power supply.

The use of four-terminal capacitors in switching power supplies is beneficial due to their excellent high-frequency characteristics. They provide an effective means to reduce the pulsating component of the output voltage and suppress switching spike noise.

Switching regulated power supplies are equipped with comprehensive protection features. In addition to the primary function of stabilizing voltage, they also incorporate various protection mechanisms. These include overvoltage protection (when the output voltage exceeds +10%), undervoltage protection (when the output voltage drops below -10%), phase loss protection, short circuit protection, overload protection, and optional spike suppression. Spike suppression is particularly useful for mitigating the impact of high-amplitude, narrow pulse width spikes that may occur in the power grid, preventing damage to electronic components with low voltage tolerance.

High-frequency aluminum electrolytic capacitors also have a multi-core form, which divides the aluminum foil into several shorter segments and connects them in parallel with multiple leads to reduce the resistance component in the capacitive reactance.

Laminated capacitors are also called non-inductive capacitors. Generally, the cores of electrolytic capacitors are rolled into cylinders, and the equivalent series inductance is relatively large; the structure of laminated capacitors is similar to that of books, and the magnetic flux generated by the flowing current is counteracted, thus reducing the value of the inductance and having better high-frequency characteristics. This kind of capacitor is generally made into a square shape, which is easy to fix, and can also appropriately reduce the volume of the machine. 2. Snubber and commutation capacitor

Snubber and commutation capacitor

With the increasing rated power, faster switching speed, and higher rated voltage of gate-controlled semiconductor devices, the requirements for capacitors in snubber circuits go beyond sufficient withstand voltage, capacity, and excellent high-frequency characteristics.

In high-power power electronic circuits, where the switching speed of IGBT is typically less than 1μs, it is necessary for the capacitor in the snubber circuit to handle voltage change rates (dv/dt) that are greater than V/μs or even multiple times of V/μs.

Ordinary capacitors, such as metallized capacitors with dv/dt<100V/μs, special metallized capacitors with dv/dt≤200V/μs, and special double metallized capacitors with small capacity (less than 10nF) with dv/dt≤1500V/μs, face difficulties in withstanding the high repetition rate peak current impact that occurs at such huge magnitude and high speed. These conditions can potentially lead to damage in power electronic circuits.

At present, special capacitors for snubber circuits, that is, metal foil electrodes, can withstand large peak currents and RMS current impacts, such as: smaller capacity (below 10nF) can withstand a voltage change rate of 100000V/μs~455000V/μs, 3700A peak current and 9A RMS current (such as CDV30FH822J03); 0V/μs and 1000A peak current impact.

In absorption circuits, non-inductive capacitors such as metallized capacitors and metal foil capacitors exhibit different performances, and their similar-shaped but different specifications make them incompatible. The size of the capacitor impacts its dv/dt and peak current capacity. Generally, larger capacitors have smaller dv/dt and peak current capabilities.

The snubber circuit capacitor operates with small duty cycles for high peak currents and not very high RMS currents. A similar circuit is found in the commutation capacitor of a thyristor inverter. While the required dv/dt for this capacitor is lower than that of the snubber capacitor, it experiences large peak currents and RMS currents. Ordinary capacitors are insufficient to meet the current requirements in such applications.

In certain specialized applications, energy storage capacitors need to be rapidly and repeatedly discharged with extremely low discharge circuit resistance and minimal parasitic inductance. In these cases, parallel use of absorption capacitors becomes necessary to ensure long-term reliability.

Resonant capacitor

Resonant converters, such as resonant switching regulated power supplies and resonant capacitors in the resonant circuit of thyristor intermediate frequency power supplies, experience high current flow during operation. For instance, improper selection of the resonant capacitor specification in an electronic ballast can lead to capacitor damage caused by the large resonant current, even if the voltage does not reach the breakdown voltage.

When a circuit contains a capacitor and an inductor connected in parallel, there are small periods of time where the voltage across the capacitor gradually increases while the current decreases. Simultaneously, the current through the inductor gradually increases while the voltage across it decreases. In another small period of time, the voltage across the capacitor gradually decreases while the current increases. At the same time, the current through the inductor gradually decreases while the voltage across it increases. The voltage can reach both positive and negative peak values during these oscillations, and the direction of current also changes between positive and negative. This phenomenon is referred to as electrical oscillation in the circuit.

The circuit oscillation phenomenon may gradually disappear, or it may continue to be maintained. When the oscillation continues, we call it constant amplitude oscillation, also known as resonance. Resonance time The time during which the two forging voltages of the capacitor or inductor change for one cycle is called the resonance cycle, and the reciprocal of the resonance cycle is called the resonance frequency. The so-called resonant frequency is defined in this way. To sum up, in modern power supply technology, capacitors with different performances are required for different applications, and they cannot be mixed, abused, or misused, so as to eliminate damage that should not occur as much as possible and ensure product performance.

How to understand complex DC-DC circuit diagrams?

In essence, the core issue lies in the incorrect learning approach. Traditional subject teaching often follows a linear path, starting with explaining specific knowledge points chapter by chapter and expecting learners to later connect the dots and understand the relationships between different chapters. This approach can overwhelm individuals with excessive technical details right from the start, leading to confusion and difficulties in fully grasping and effectively utilizing the knowledge.

This approach deviates from the natural process of human cognition when encountering new things. Think about how we typically learn about something new. We first hear its name, develop an interest, inquire about its concept, and understand its capabilities and advantages. Then we try using it in our lives repeatedly until we become proficient and emotionally familiar with it. If it eventually breaks down and we are unwilling to spend a lot of money on repairs, we may purchase a book to learn about its principles. When we see schematic or mechanical diagrams, we may suddenly realize the ingenuity behind its design. As people in the community start buying the same item and seek your help for repairs, you gradually become an expert in that field.

This learning method aligns with human cognitive habits: starting with a holistic and perceptual understanding, then progressing to practical application, followed by delving into the principles, and finally achieving mastery through practice, innovation, and transformation.

It is not difficult to understand the circuit

Understanding complex DC-DC circuit diagrams requires a systematic approach. Here are the steps to analyze such circuits:

- Set your mindset: Don’t be overwhelmed by the complexity. Remember that complex circuits are built using basic circuits.

- Acquire basic knowledge: Familiarize yourself with commonly used basic circuit structures.

- Analyze the circuit: Before diving into the details, answer these questions:

- What is the overall purpose of the DC-DC circuit? What core function does it achieve?

- What is the technical nature of this core function? What specific tasks does it accomplish?

- What are the basic circuit structures that can be employed to realize this function?

- What are the differences between the basic circuit structures and the final implemented function?

- How can the shortcomings or defects of the basic DC-DC circuit be resolved?

By addressing these questions, you can systematically understand the various modules within the complete circuit.

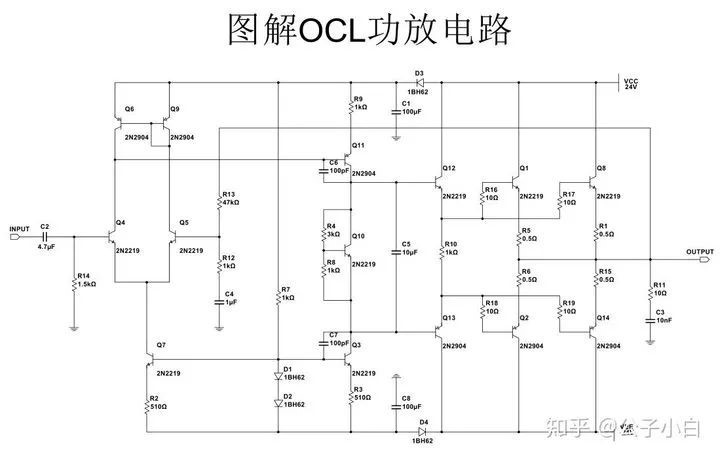

Does it look complicated at first glance?

Let’s follow the steps just now!

What does this circuit as a whole do? What is the core function realized?

Implement audio amplification.

What is the nature of this core function? That is, from a technical point of view, what exactly has been done?

Realize power amplification, specifically voltage amplification and current amplification.

What are the basic circuit structures that can be used to realize this function?

Voltage amplification: common emitter amplifier, common base amplifier, differential amplifier, op amp.

Current amplification: common collector amplifier, totem pole.

What is the difference between the basic circuit and the final implemented function?

To achieve voltage amplification, the operational amplifier needs to provide positive and negative power supplies, and the voltage range of the general operational amplifier is limited, so it cannot be made too high.

Common base circuit input resistance is too low, not suitable for audio signal amplification.

The output impedance of the common emitter circuit and the differential circuit is high, and the magnification of the actual load is not enough.

Common collector and totem pole, single stage with limited current gain.

How to solve the defects of the basic circuit?

Not enough voltage gain? Do a wave of multi-level amplification.

High output impedance? Active load is replaced.

Not enough current gain? Multi-stage follower with totem pole.

In a word, if you can’t do it to death, you can do it to death. If one level is not enough, go up to multiple levels. If one circuit is defective, then multiple hybrids.

After figuring out the above questions, let’s look at this circuit diagram again, looking from left to right, is it clear at a glance?

Differential circuit with active load to achieve voltage amplification -> common emitter amplifier with active load to continue voltage amplification -> emitter follower to achieve current amplification -> totem pole to continue current amplification.

Leave a Reply